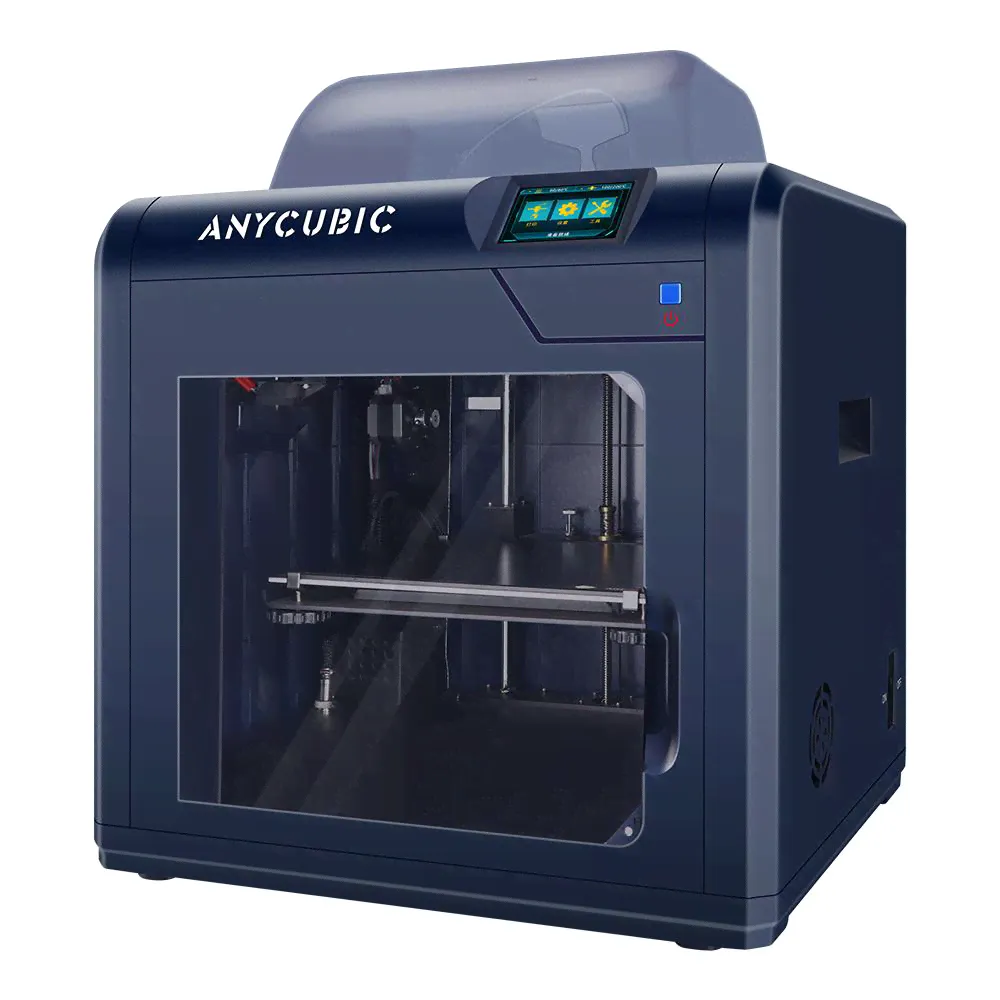

Описание

Anycubic 3Max Pro 4 2.0D printer is an updated version of the beloved printer. This printer offers ideal conditions for printing on a wide variety of materials, including rubbery ones. Large print area, closed housing, heated platform - all this will help you to achieve high quality of your models. The 4Max Pro 2.0 has a very modern design and, despite its modeling area, is very compact. The Anycubic 4Max Pro 2.0 printer is equipped with a large enough workspace. This ensures comfortable work and the ability to create large volumetric products. The basis of the printer is a steel frame created from a profile with high strength indicators. It is equipped with special anti-shock pads that are designed to reduce vibrations. To move the working surface, guide elements are used, which are connected to the table using bushings treated with graphite grease. This ensures smooth and precise movement of the plane. During operation, the printer installation does not emit unnecessary noise. The design uses motor drivers to keep the noise within 50 dB. This level does not create discomfort for people. The closed printer system also reduces the smell of heated filament. It is eliminated by means of carbon filters, which are installed in front of the fan. Anycubic 4Max Pro 2.0 comes pre-assembled. The printer is perfect for both novice users and professional use. Specifications: Print technology: FDM (Fused Deposition Modeling) Build volume: 270mm (L) × 210 (W) × 190mm (H) Layer resolution: 0,05-0,3mm Positioning accuracy: X / Y / Z 0,01 .0,0125 / 0,00125 / 1,75mm Number of extruders: one Nozzle diameter: φ0,4 / 20mm Print speed: 150 ~ 50mm / s (8mm / s recommended) Supported materials: ABS, TPU, PLA , HIPS, etc. Ambient operating temperature: 40–260 ° C Extruder operating temperature: max. 100 ° C Operating platen temperature: max. 3ºC Slicer software: Cura, Simplify110D, Repetier-HOST Software input formats: .STL, .OBJ, JPG, PNG Software output formats: G Code Connectivity: SD c